The hand is the most important tool for the employee. They are fragile and highly susceptible and are the most vulnerable parts of the body at work. Well-chosen personal protective equipment guarantees good safety. However, it is important to correctly identify the risks to which your hands are exposed and to be able to choose the right protective gloves based on your environment and professional activities.

What are the different risks associated with hand protection?

Tested, our hands are exposed to countless aggressions: cuts, electric shocks, crushes, allergies, burns, tears, etc. These are risks that can have irreversible consequences for the health of those who control them. For this reason, it is important to identify business risks and select appropriate gloves that meet European standards.

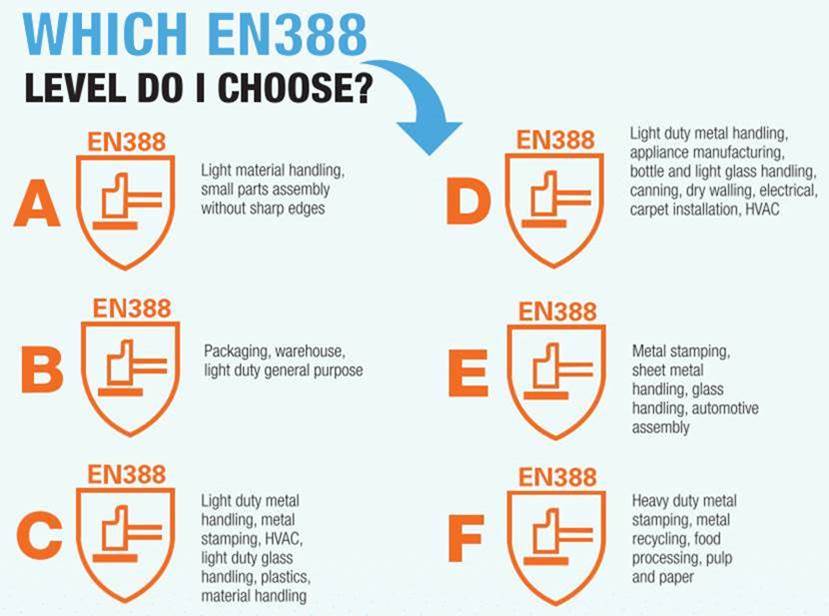

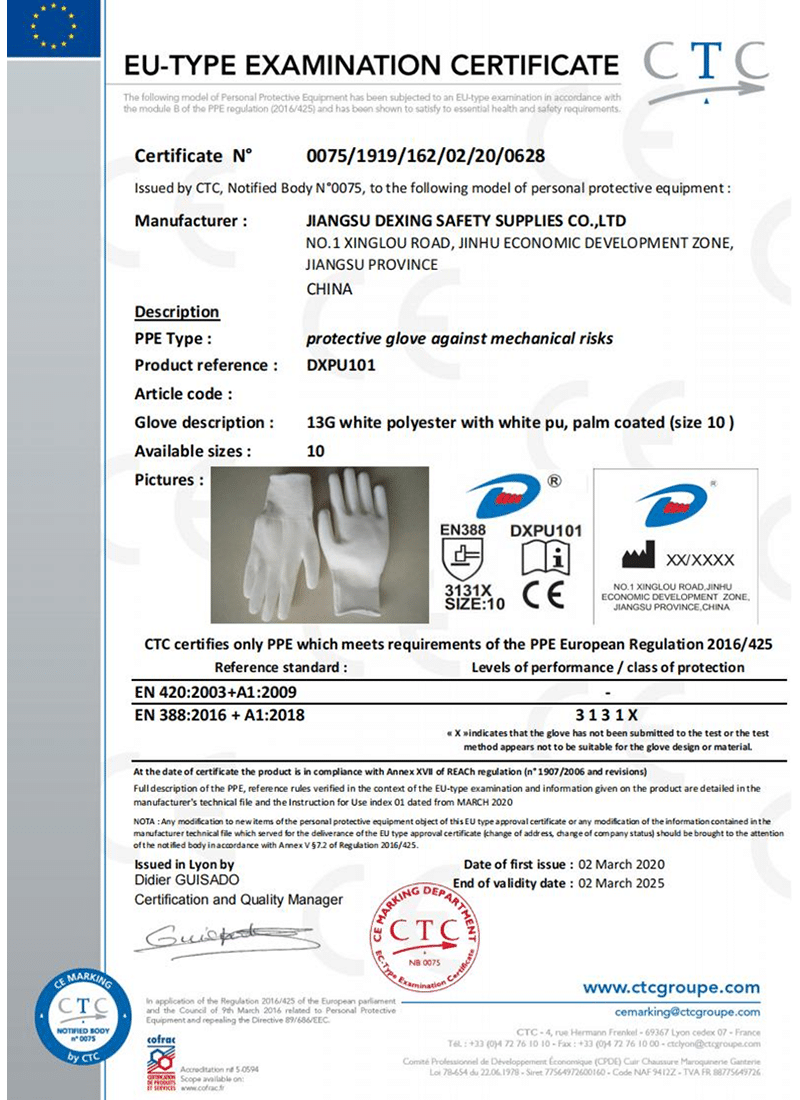

What is the mechanical risk?

In workshops and factories, many tools and machines operate by mechanical action. This can lead to many injuries: blade cuts, scratches, tears, punctures. The use of material in mechanical equipment can cause serious injuries. This mechanical hazard is defined in European Standard EN 388 and is indicated by the icon on the protective gloves.

What is the heat risk?

Thermal hazards occur in many sectors, such as welders, bakers, foundries, or cold areas in the food industry. Heat and cold pose a serious risk of burns and frostbite, which makes the task considerably more difficult.

Thermal protective gloves are regulated by the EN 407 standard, which evaluates performance levels in relation to thermal risks such as combustion behavior, contact heat resistance, convective or radiant heat, and molten metal splashes. Cold protective gloves according to EN 511. They are selected based on their resistance to contact or convective cold or water.

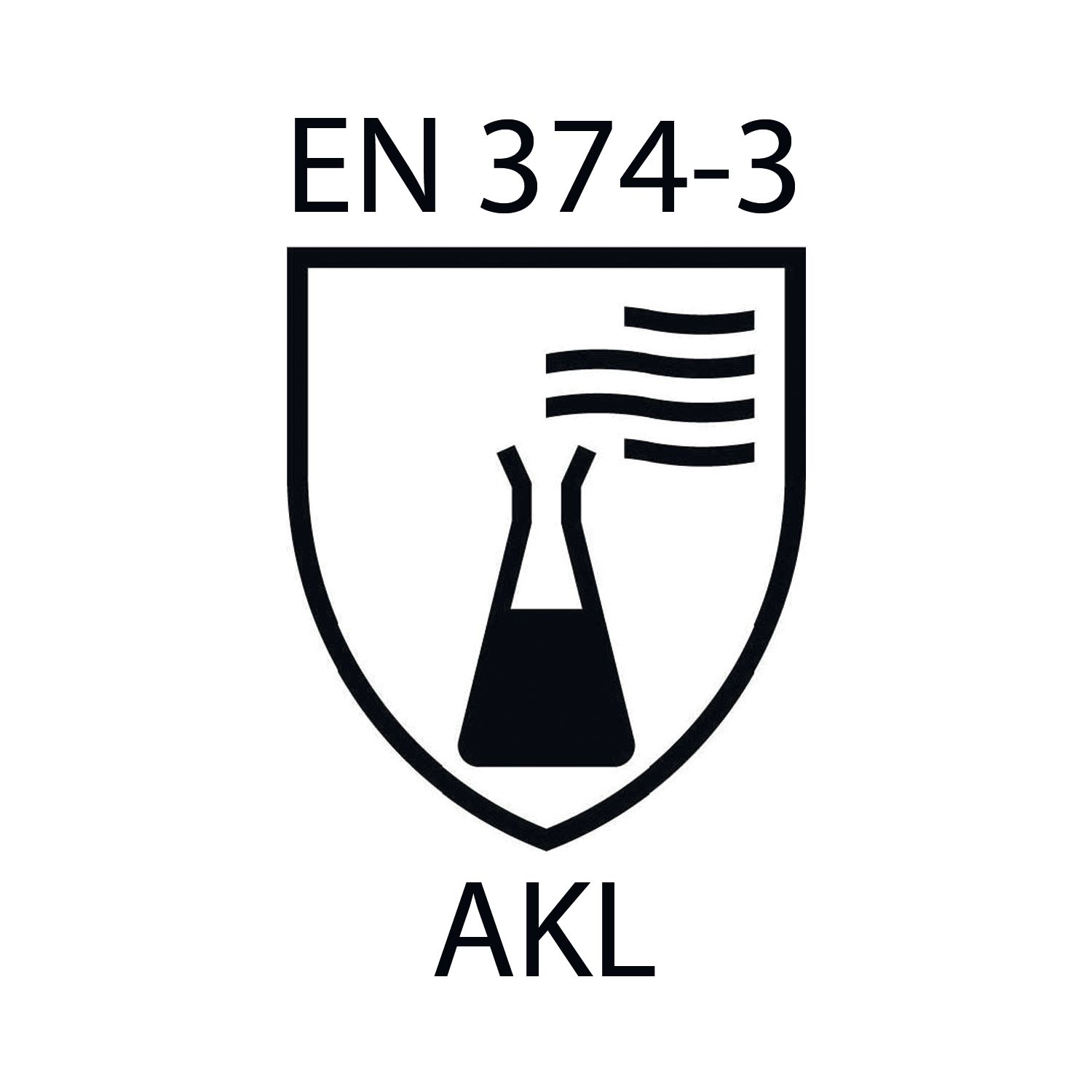

What is a chemical hazard?

The biological and pharmaceutical industries, among others, face chemical risks when handling hazardous products. This can result in skin irritation such as eczema, severe allergies, or even burns. Protective gloves marked EN 374 limit the chemical risks of spraying substances. Their impermeability and water resistance guarantee maximum protection. The standard also covers the biological risks of microorganisms and viruses.

What is the electrical risk?

Protection against electric shock and electrostatic discharge is essential. Protective gloves suitable for this risk are regulated by EN 60903 and EN16350 standards. These standards indicate the compatibility of personal protective equipment with the risk of electric shock and electrostatic discharge.

What kind of protective gloves should I choose?

Each type of protective glove is designed for the specific material and the level of durability required by the CE marking. However, protective gloves cannot give up comfort, well-being guarantees flexibility for employees when performing tasks.

Cut off protective gloves

Sharp protective gloves are very resistant to mechanical hazards. Performance yarns and technical yarns are great materials for these protective gloves.

Typically without seams, reinforcements, flexible wrists and the right size fabric and / or coated cut protection gloves have one goal: high durability up to the fingertips, complete safety.

thermal gloves

Gloves that protect against cold and heat prevent the risk of discomfort and frostbite on the hands. Cold-resistant gloves protect your hands in winter against occasional freezing temperatures in outdoor workplaces. They are also excellent insulators for handling objects in cold rooms.

PVC-coated gloves are made of 100% insulating acrylic fleece and elastic cuffs, which guarantee good performance against the cold. It offers excellent durability and water resistance for complete comfort against the cold. Cold resistant gloves are ideal for the food industry. Agile and agile COLDSKIN gloves are woven from 100% breathable heat-regulating yarns that keep your hands comfortable and warm. Integrated elastic fibers improve flexibility and flexibility of use.

Heat resistant gloves are usually made

Post time: Feb-09-2022